HOESCH products

As individual as your requirements. .

Alloying Additives

By adding HOESCH alloying elements, aluminum obtains the desired specific properties such as strength, ductility, corrosion resistance, heat resistance, etc.

HOESCH Alloying Additives are produced by powder metallurgy and are characterized by chemical purity and performance in the production of specific alloys.

Delivery forms

Tablets

Briklets

Delivery forms

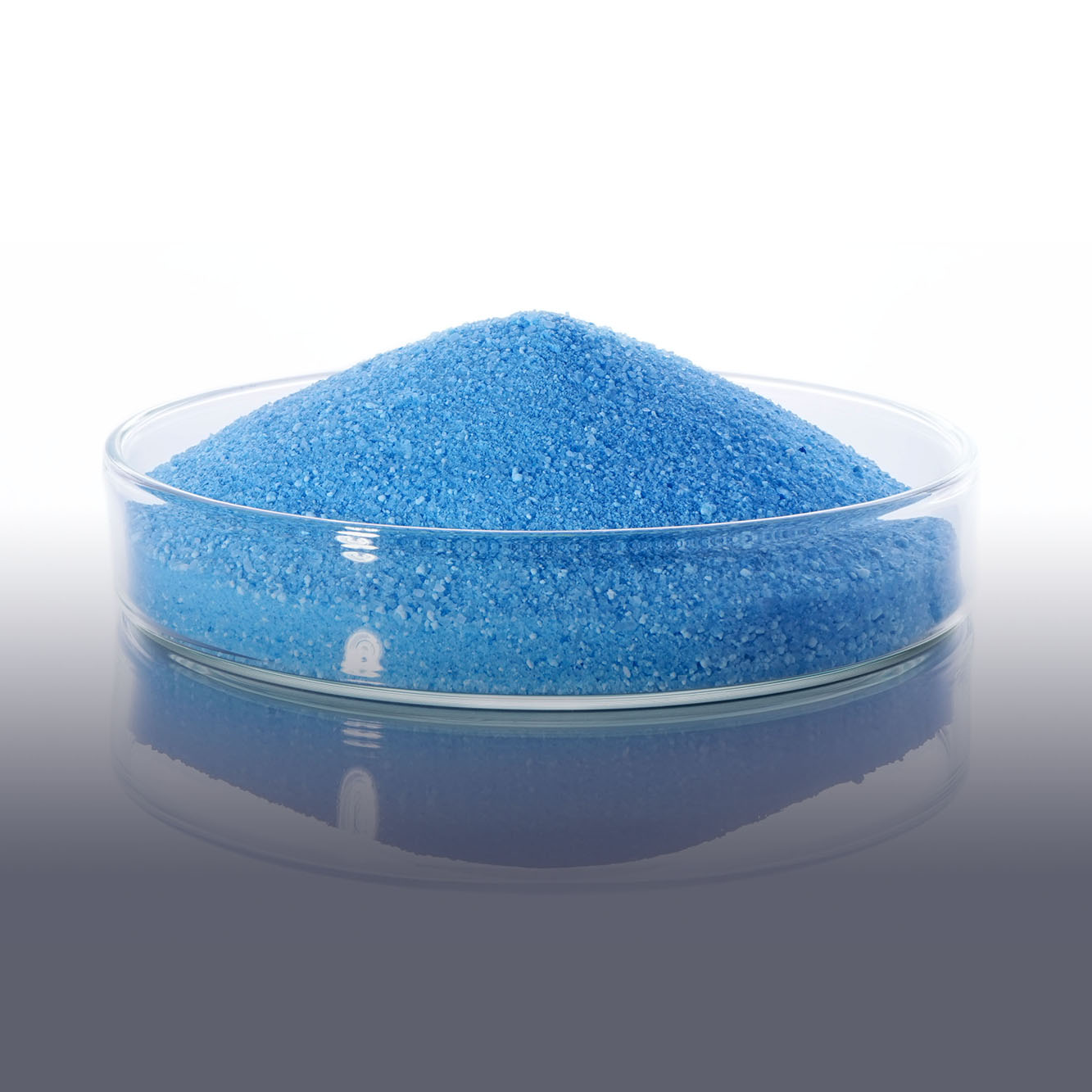

Powder

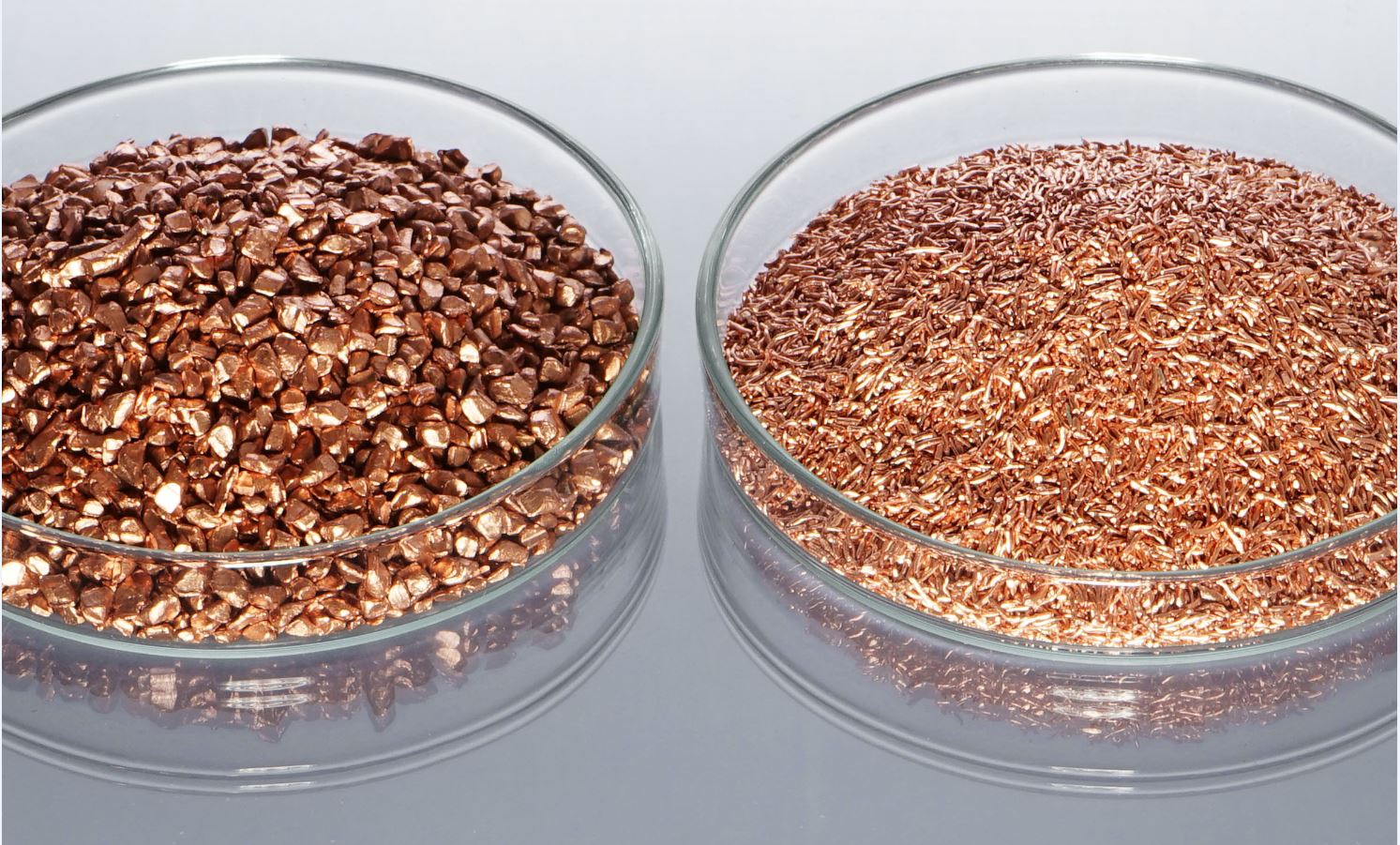

Granules

Tablets

Delivery forms

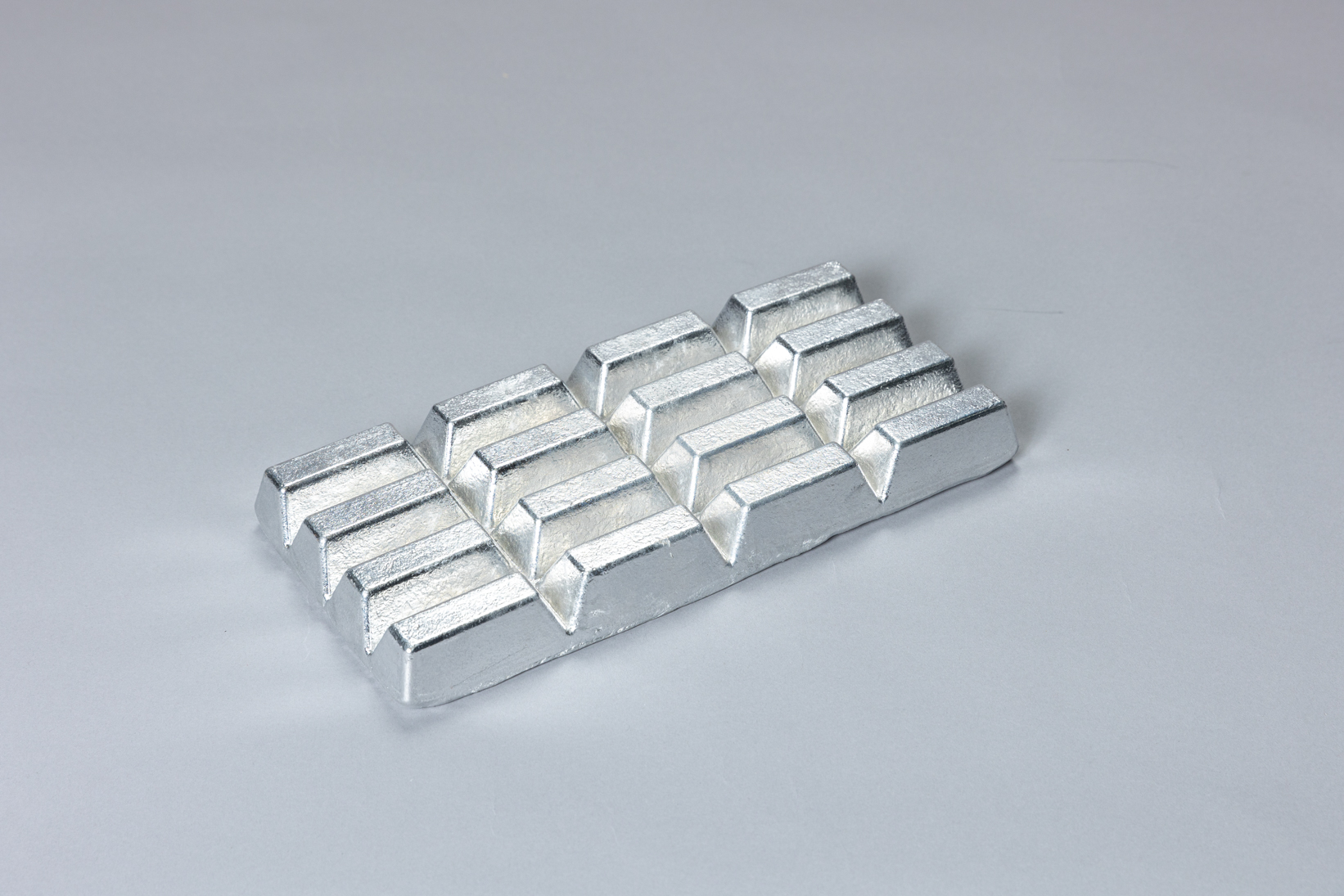

Ingots

Bars / Rods / Puks

Wire coils

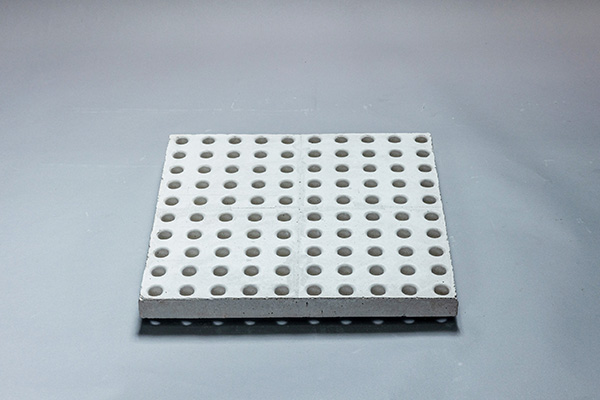

Waffle Plates

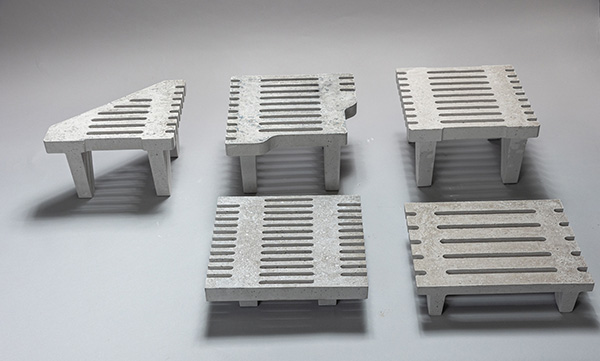

Waffle Plates

Pure metals

Magnesium

Manganese

Silicon

Titanium

Copper

HOESCH Ceral® Filtergrids

HOESCH Ceral® Sink Plates

HOESCH Ceral® filter boxes

HOESCH Ceral® cast drain